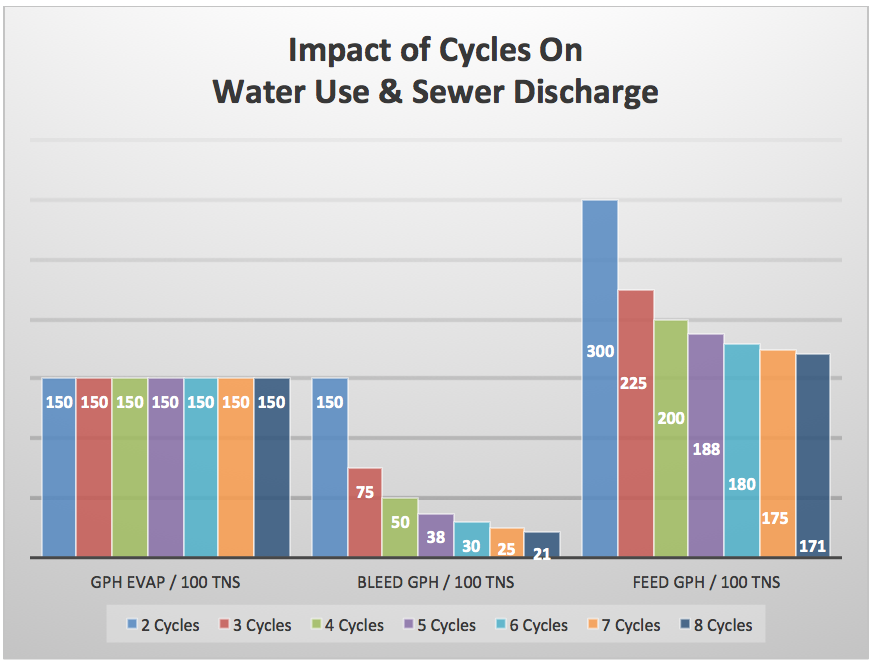

Recently Mr. Greg Bush of Sybase ( an SAP Company ) in Dublin CA, decided to decrease water use in his 250 Tn cooling system with the implementation of Sustainable Water Solutions LLC’s Nereus cooling water treatment and control system.

Nereus is a combination of state of the art safe water treatment chemicals, full gauging, process monitoring and a cloud based reporting & analysis system that allow users to maximize cooling tower cycles of concentration while maintaining clean heat transfer surfaces. In the case of Sybase, the cooling tower was running 2 cycles of concentration prior to Nereus implementation.

The target for the Nereus system was to get to and stay at 7 cycles of concentration while maintaining clean heat transfer surfaces.

Formulae Used

Evaporation = 1.5 GPH / Tn

Bleed = Evaporation / ( Cycles -1 )

Latent Heat of Evaporation = 970 BTU / Lb

Weight of water = 8.34 Lbs

Tower Make Up Water Averages 600 Conductivity

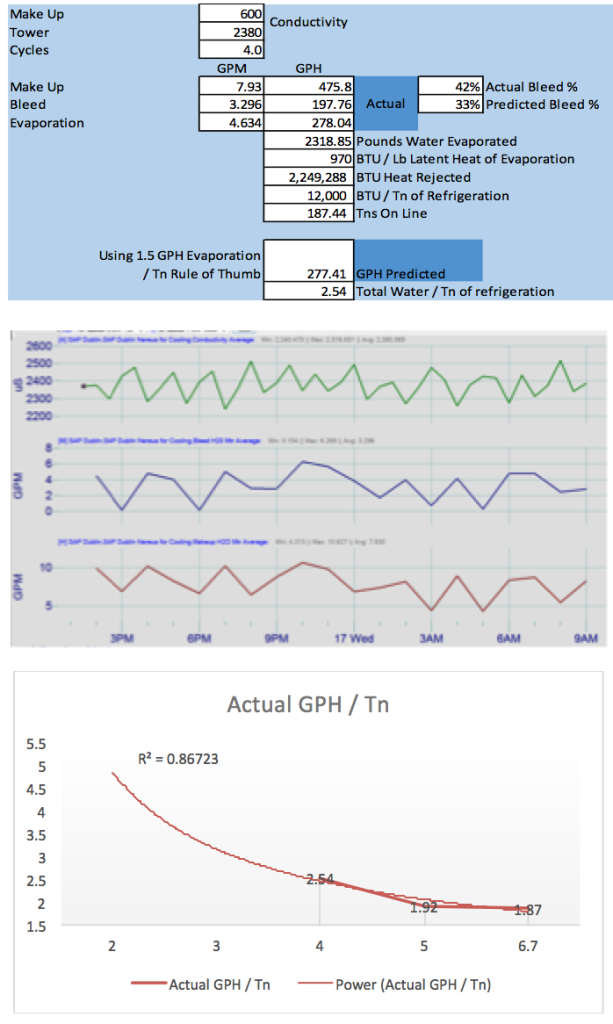

In First time period the graph below shows an average of 2,380 conductivity was held in the period 9/16 – 9/17 ( 4.0 Cycles ). In the same time period an average of 7.93 GPM of makeup water was added to the tower while 3.296 GPM was removed via bleed.

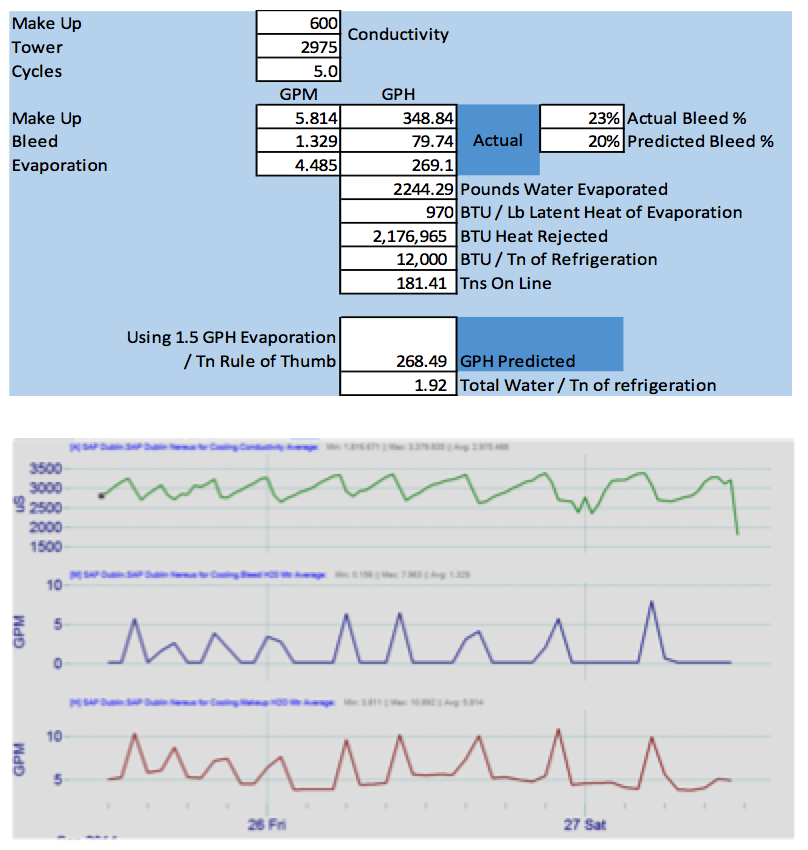

In second time period the graph below shows an average of 2,975 conductivity was held in the period 10/25 – 10/27 ( 5.0 Cycles ). In the same time period an average of 5.814GPM of makeup water was added to the tower while 1.329 GPM was removed via bleed.

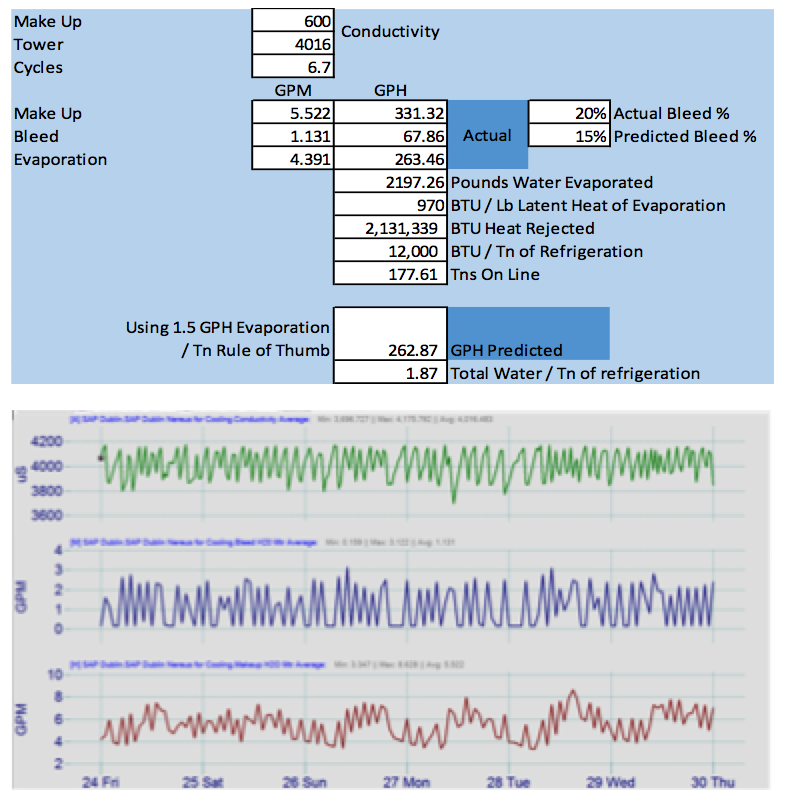

In the third time period an average of 4,016 conductivity was held in the period 10/24 – 10/30 ( 6.7 Cycles ). In the same time period an average of 5.552 GPM of makeup water was added to the tower while 1.13 GPM was removed via bleed.